Cleanroom Cable Solution

Cleanroom Cable Solution

Cable assembly and jacket fixation methods comply with cleanroom-grade standards, ensuring optimal transmission quality. Low particle emission design; suitable for environments with stringent cleanliness requirements.

This is a customized service. Please directly contact our service email at support.tw@comoss.com by clicking the button below.

Couldn't load pickup availability

Delivery Time

Delivery Time

By request

General Specifications

General Specifications

By request

Share

Cleanroom Cable Solutions

PTFE Sleeve

1. Uses a flexible and weather-resistant PTFE protective sleeve, capable of bundling multiple cables. Suitable for drag chains.

2. Working temperature from -65℃ to 200℃.

Fluoro-Elastomer Heat Shrink Tubing (Applicable for Dynamic Cables)

1. Uses fluoro-elastomer heat shrink to cover single cables. The sheathing material offers excellent flame retardancy and chemical resistance.

2. Working temperature from -55℃ to 200℃.

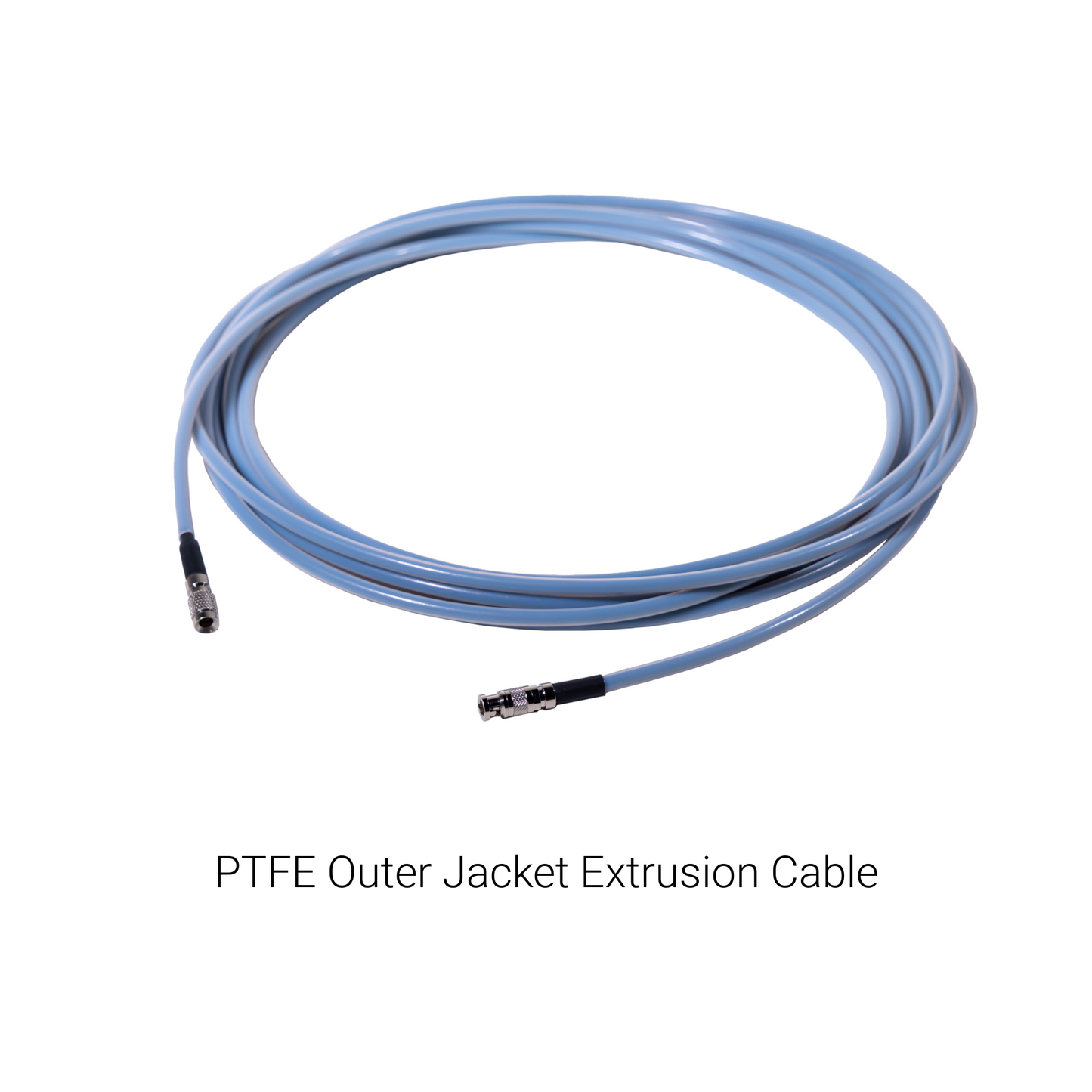

PTFE Outer Jacket Extrusion (Applicable for Dynamic Cables)

1. Uses PTFE resin extruded at high temperatures to cover the conductor or cable bundle. This process ensures uniform and tight sheathing. Provides high abrasion resistance and stable resistance against mechanical pulling & bending, suitable for high-frequency multi-axis mobile equipment, such as robotic arms.

2. Working temperature from -65℃ to 200℃.

Application

1. Semiconductors

2. Flat Panel Displays

3. Medical

4. Aerospace

5. IC Packaging/Testing

6. Labs

7. Precision Engineering

8. Optics

9. Laser Technology

10. Food Processing